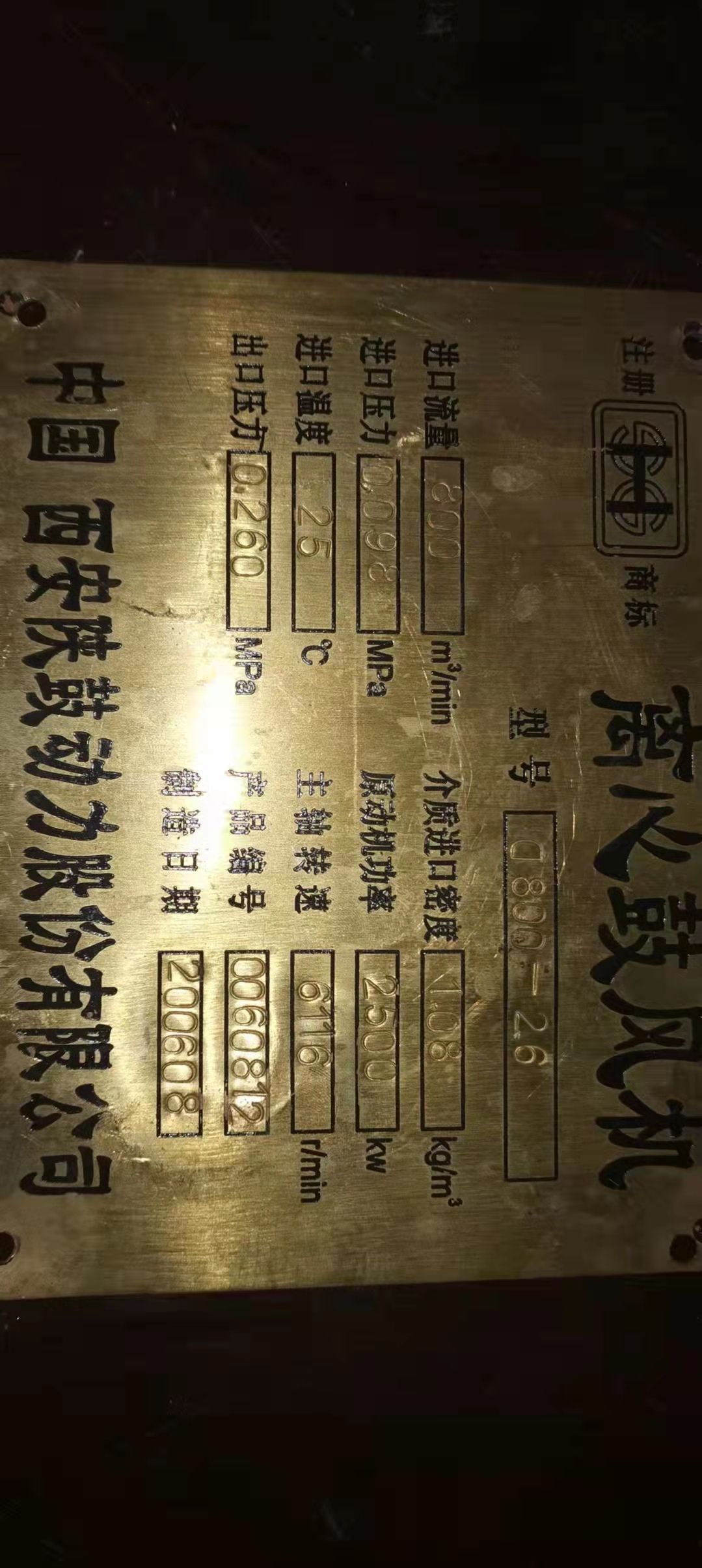

Used Blast Furnace Centrifugal Fan

Product Details:

Used Blast Furnace Centrifugal Fan Price And Quantity

- 1000000.00 - 10000000.00 USD ($)/Container

- 1 Container

- 1000000 USD ($)/Container

Product Description

D Series blower is used to provide sufficient air for smelting blast furnace orChemical industry, it is an important part of the blast furnace production.

This type blowerïs inlet and outlet both are downward, the traditional two floors are used for the layout. The core unit of centrifugal blower, gear box and motor are arranged in the second floor, the control is located next to the machine train, which is easy to observe and operate. The lube oil station, valves, inlet & outlet valves are arranged in the first floor because of high discharge temperature, which need very good ventilation condition.

This type blower adopts the most advanced high efficient three-dimensional centrifugal blower Design and manufacturing technology. The integral machine train is featured by good quality and reliable condition and the efficiency is 8ï10% higher than normal two-dimensional design.

The three space torsional blades, impeller disc and main shaft for the whole impeller of rotor is made up of high strength alloy steel, the impeller shall be made integral heat treatment and process quality conditioning after welding, which can guarantee the impellerïs whole crystal organization precision and also eliminate stress after welding, thus greatly increase the safety and reliability of impeller. Each impeller shall be done over-speed test with 15% working speed and the whole rotor shall be done with high precise dynamic balance test to guarantee stable and reliable operation.

Both the casing and diaphragm use resin sand casting, with higher density and bright appearance, each joint surface is sealed and reliable after precision machine and scraping.

Scope of supply:

|

Item |

Name |

Contains |

|

1 |

Fan |

Three-dimensional impeller rotor, casing, base frame, diaphragms and sealing, bearing and bearing base, coupling and protection hood, gas & oil port counter-flange, Coupling and shield for gearbox and fan, Coupling and shield for gearbox and motor,Diaphragm coupling, |

|

2 |

Oil Lubrication station |

Oil pump,cooler,Pressure gauge.etc |

|

3 |

Overhead oil tank |

|

|

4 |

Gearbox |

Bearing and base frame, pairs of gear and bearing pad with hard gear surface. |

|

5 |

Whole Air valves and actuation mechanism |

Inlet electric control valve,Outlet baffle check valve,Outlet electric blow valve,Electric blow-off valve,Anti-surge valve |

|

6 |

Inlet & outlet compensator |

|

|

7 |

Anti-surge control and operation status monitoring system |

Primary and secondary instrument, anti-surge automatic control system, computer monitoring system, instrument panel, anti-surge electric control valve etc.. |

|

8 |

Self cleaning inlet air filter |

|

|

9 |

Blow-off silencer |

|

|

10 |

Motor |

6.6kv,11kv |

|

11 |

Control cabinet with soft starter |

High pressure run cabinet,star cabinet,soft starter,

Work station |